Prepared By:-

O.B DEVELOPERS

(STRUCTURE AUDIT AGENCY)

Email- strutureauditagency@gmail.com

Call-+91-9717924616

www.structureauditagency.com

Executive Summary:

Based on the Visual Inspection & NDT Results

Of all the Wire of the Existing structure

- In order to assess the structural stability of the building, following tests were conducted at site

- Wire Thickness Reduction Test : This Test is performed to check the reduction in the wire diameter due to rusting

- Estimated reduction of the thickness varies from 0.01mm to 0.09mm.

- Wires above the false ceiling are less rusted than the wire hanging outside as per test.

- Wire adequacy analysis

- The wire is analysis for the load hanging over it with a safety factor of 1.5 X Existing Load.

- The wire is found to be safe for the existing load only there is need to repair the existing condition of wire as per recommendations mention in the report.

Table of Contents

| Sr.No. | Description of NDT Reports | Page No. | |

| 1 | Introduction, Scope of Work | 4-5 | |

| 2 | Methodology For Performing Non-Destructive Tests | 6 | |

| 3 | NDT Test Results & Interpretation | ||

| 3.1 | Wire Thickness Reduction Results | 7-10 | |

| 3.2 | Wire Strength Analysis Results | 11 | |

| 4 | Testing Photographs & Recommendations | 12 | |

1. Introduction

- Introduction

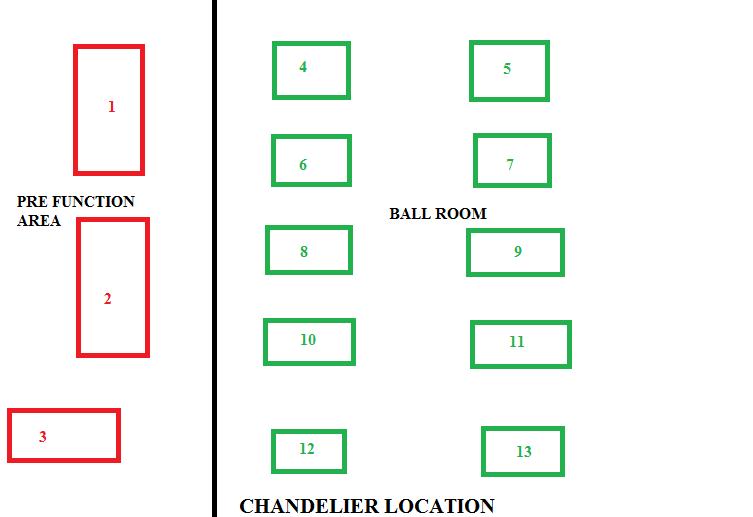

- The existing structure at Crowne Plaza, Mayur Vihar ,Delhi.R.C.C framed structure. M/s Eros Group has awarded the work to O.B Developers for conducting condition assessment of wire using Non-destructive testing.

This report pertains to the asserted safety appraisal and structural health assessments standards. In this report description of the damaged portions of the wire, objectives of the investigation and survey, general methodology and test procedures etc. are given, followed by details of the observations recorded at the site and results of in-situ and laboratory tests.

1.2. Walkover survey and visual inspection

First and foremost activity in a condition survey and structural investigation, especially in rusting of wire, is a walk over survey or systematic visual inspection so as to gather readily available information about the structure in question.

1.3. Objectives of the overall investigation

The overall objective of the investigation carried out for the structure is to obtain an up to date account of the health condition of the wire so that appropriate repair measures can be taken up to make up for the damages sustained. Keeping this in view the basic objectives of the investigation formulated is as given below.

- To assess the existing condition of the structural elements.

- To determine the extent of damages in the structure, so as to undertake suitable remedial measures for rehabilitation of the structure.

1.4 Scope of work and selection of tests

In-situ tests tests have been selected based on the visual inspections carried out and as detailed in the scope of work. The selection of tests has been done so as to meet the overall objective of the NDT study and the observations made during a quick walk over survey. Test were conducted for the evaluation of the Structure:

The Non-Destructive Test carried out for health assessment and structural audit of the RCC structures are given below

.

- Wire Thickness Reduction Test : This Test is performed to check the reduction in the wire diameter due to rusting

2. TESTING PROCEDURE

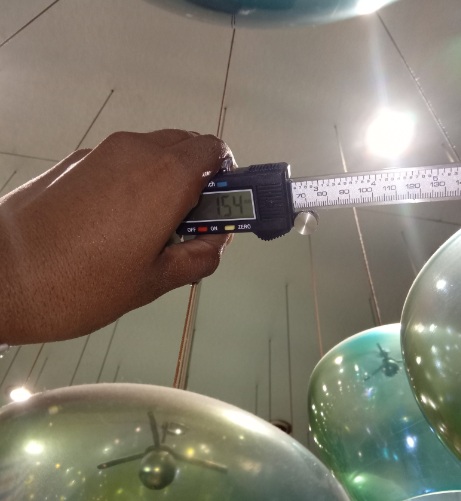

To check the thickness reduction of the wire due to corrosion following steps are involved:-

- Checking the existing thickness of wire with rust with the help of vernier caliper.Clean the rust with the help of rust removal and then clean the surface.Measure the wire thickness now with the help of vernier caliper.The thickness reduction would be the difference between before and after reading difference.

| S.No | Before Rust removal reading | After rust removal reading | Thickness reduction |

| 1 | A | B | a-b |

3. TEST RESULTs INTERPRETATION

Test Certificate:- wire THICKNESS REDUCTION result

Pre function area

| Chandelier No. 1 | Thickness reduction(mm) | |||||

| S.NO. | Before Rust Removal(mm) | After Rust Removal(mm) | ||||

| 1 | 1.58 | 1.56 | 0.02 | |||

| 2 | 1.57 | 1.56 | 0.01 | |||

| 3 | 1.53 | 1.52 | 0.01 | |||

| 4 | 1.51 | 1.51 | 0 | |||

| 5 | 1.57 | 1.57 | 0 | |||

| 6 | 1.64 | 1.57 | 0.07 | |||

| 7 | 1.61 | 1.53 | 0.08 | |||

| 8 | 1.63 | 1.55 | 0.08 | |||

| 9 | 1.59 | 1.52 | 0.07 | |||

| 10 | 1.56 | 1.51 | 0.05 | |||

| 11 | 1.65 | 1.57 | 0.08 | |||

| 12 | 1.62 | 1.56 | 0.06 | |||

| 13 | 1.62 | 1.59 | 0.03 | |||

| 14 | 1.68 | 1.62 | 0.06 | |||

| 15 | 1.67 | 1.62 | 0.05 |

| Chandelier No. 2 | Thickness reduction(mm) | |||||

| S.NO. | Before Rust Removal(mm) | After Rust Removal(mm) | ||||

| 1 | 1.57 | 1.56 | 0.01 | |||

| 2 | 1.61 | 1.59 | 0.02 | |||

| 3 | 1.58 | 1.51 | 0.07 | |||

| 4 | 1.61 | 1.53 | 0.08 | |||

| 5 | 1.63 | 1.55 | 0.08 | |||

| 6 | 1.62 | 1.55 | 0.07 | |||

| 7 | 1.58 | 1.55 | 0.03 | |||

| 8 | 1.56 | 1.53 | 0.03 | |||

| 9 | 1.55 | 1.52 | 0.03 | |||

| 10 | 1.53 | 1.52 | 0.01 | |||

| 11 | 1.61 | 1.58 | 0.03 | |||

| 12 | 1.62 | 1.54 | 0.08 | |||

| 13 | 1.58 | 1.55 | 0.03 | |||

| 14 | 1.56 | 1.53 | 0.03 | |||

| 15 | 1.53 | 1.51 | 0.02 |

| Chandelier No. 3 | Thickness reduction(mm) | |||||

| S.NO. | Before Rust Removal(mm) | After Rust Removal(mm) | ||||

| 1 | 1.59 | 1.57 | 0.02 | |||

| 2 | 1.59 | 1.58 | 0.01 | |||

| 3 | 1.62 | 1.58 | 0.04 | |||

| 4 | 1.61 | 1.56 | 0.05 | |||

| 5 | 1.6 | 1.57 | 0.03 | |||

| 6 | 1.59 | 1.54 | 0.05 | |||

| 7 | 1.58 | 1.53 | 0.05 | |||

| 8 | 1.62 | 1.55 | 0.07 | |||

| 9 | 1.59 | 1.57 | 0.02 | |||

| 10 | 1.58 | 1.54 | 0.04 |

Ball room area

| Chandelier No. 4 | Thickness reduction(mm) | |||||

| S.NO. | Before Rust Removal(mm) | After Rust Removal(mm) | ||||

| 1 | 1.57 | 1.52 | 0.05 | |||

| 2 | 1.58 | 1.53 | 0.05 | |||

| 3 | 1.62 | 1.59 | 0.03 | |||

| 4 | 1.64 | 1.56 | 0.08 | |||

| 5 | 1.63 | 1.55 | 0.08 | |||

| 6 | 1.62 | 1.59 | 0.03 | |||

| 7 | 1.55 | 1.51 | 0.04 | |||

| 8 | 1.62 | 1.54 | 0.08 | |||

| 9 | 1.59 | 1.56 | 0.03 |

| Chandelier No. 5 | Thickness reduction(mm) | |||||

| S.NO. | Before Rust Removal(mm) | After Rust Removal(mm) | ||||

| 1 | 1.61 | 1.52 | 0.09 | |||

| 2 | 1.55 | 1.51 | 0.04 | |||

| 3 | 1.54 | 1.53 | 0.01 | |||

| 4 | 1.59 | 1.55 | 0.04 | |||

| 5 | 1.62 | 1.58 | 0.04 | |||

| 6 | 1.72 | 1.62 | 0.1 | |||

| 7 | 1.55 | 1.52 | 0.03 | |||

| 8 | 1.58 | 1.53 | 0.05 | |||

| 9 | 1.59 | 1.5 | 0.09 | |||

| 10 | 1.6 | 1.58 | 0.02 |

| Chandelier No. 6 | Thickness reduction(mm) | |||||

| S.NO. | Before Rust Removal(mm) | After Rust Removal(mm) | ||||

| 1 | 1.8 | 1.63 | 0.17 | |||

| 2 | 1.87 | 1.55 | 0.32 | |||

| 3 | 1.57 | 1.53 | 0.04 | |||

| 4 | 1.58 | 1.5 | 0.08 | |||

| 5 | 1.8 | 1.66 | 0.14 | |||

| 6 | 1.95 | 1.85 | 0.1 | |||

| 7 | 1.58 | 1.55 | 0.03 | |||

| 8 | 1.75 | 1.52 | 0.23 | |||

| 9 | 1.8 | 1.72 | 0.08 | |||

| 10 | 1.58 | 1.51 | 0.07 |

| Chandelier No. 7 | Thickness reduction(mm) | |||||

| S.NO. | Before Rust Removal(mm) | After Rust Removal(mm) | ||||

| 1 | 1.78 | 1.68 | 0.1 | |||

| 2 | 1.54 | 1.51 | 0.03 | |||

| 3 | 1.58 | 1.55 | 0.03 | |||

| 4 | 1.64 | 1.52 | 0.12 | |||

| 5 | 1.78 | 1.6 | 0.18 | |||

| 6 | 1.52 | 1.2 | 0.32 | |||

| 7 | 1.55 | 1.53 | 0.02 | |||

| 8 | 1.53 | 1.53 | 0 | |||

| 9 | 1.52 | 1.5 | 0.02 |

| Chandelier No. 8 | Thickness reduction(mm) | |||||

| S.NO. | Before Rust Removal(mm) | After Rust Removal(mm) | ||||

| 1 | 1.55 | 1.54 | 0.01 | |||

| 2 | 1.54 | 1.53 | 0.01 | |||

| 3 | 1.62 | 1.54 | 0.08 | |||

| 4 | 1.61 | 1.52 | 0.09 | |||

| 5 | 1.57 | 1.53 | 0.04 | |||

| 6 | 1.55 | 1.51 | 0.04 | |||

| 7 | 1.71 | 1.68 | 0.03 |

| Chandelier No. 9 | Thickness reduction(mm) | |||||

| S.NO. | Before Rust Removal(mm) | After Rust Removal(mm) | ||||

| 1 | 1.53 | 1.51 | 0.02 | |||

| 2 | 1.63 | 1.6 | 0.03 | |||

| 3 | 1.63 | 1.59 | 0.04 | |||

| 4 | 1.54 | 1.52 | 0.02 | |||

| 5 | 1.53 | 1.5 | 0.03 | |||

| 6 | 1.51 | 1.5 | 0.01 | |||

| 7 | 1.62 | 1.53 | 0.09 |

| Chandelier No. 10 | Thickness reduction(mm) | |||||

| S.NO. | Before Rust Removal(mm) | After Rust Removal(mm) | ||||

| 1 | 1.6 | 1.54 | 0.06 | |||

| 2 | 1.55 | 1.53 | 0.02 | |||

| 3 | 1.59 | 1.52 | 0.07 | |||

| 4 | 1.58 | 1.51 | 0.07 | |||

| 5 | 1.73 | 1.68 | 0.05 | |||

| 6 | 1.61 | 1.57 | 0.04 | |||

| 7 | 1.64 | 1.56 | 0.08 | |||

| 8 | 1.62 | 1.59 | 0.03 |

3.2 Wire Strength Analysis Results:-

| Wire Rope Analysis for XXXXXX, Mayur Vihar, Delhi | |||

| Data Given of Wire | |||

| Young Modulus of Elasticity | 75000 | N/mm2 | |

| Self Weight of Wire | 0.003 | KN/M | (Assumed) |

| Weight to be Hanged | 0.01 | KN | |

| Assume Factor of Safety (FOS) | 15 | ||

| Design Load Wd | |||

| Load x F.O.S | 0.195 | KN | |

| Diameter of Rope | 1×7 | (As per Site Test) | |

| d= | 1.5 | mm | (As per Site Test) |

| Tensile Strength of Rope | 1100 | (As per Make Specification) | |

| Sheave Diameter | |||

| Min D/d ratio | 27 | ||

| D | 40.5 | mm | |

| Area of Useful Cross Section | |||

| A=0.4xd2 | 0.9 | mm2 | |

| Calculation of Wire Diameter | |||

| dw | 0.3787879 | mm | (2.64= √(1×7)) |

| Bending Load Wb | 0.6313131 | KN | |

| Effective Load on Rope | |||

| Wd+Wb | 0.8263131 | KN | |

| Max Load Carrying by Rope | 0.8263131 | KN | |

| Load Hanging on wire | 0.195 | KN | |

| Hence Safe |

4.1 testing photograph

|  |

4.2 RECOMMENDATION:-

- Firstly remove all rust particles from the wire with the help of rust removal spray.

- After removing all the rust then apply anti-corrosive paint over it to avoid future rusting.

- This process has to be repeated at 1 year interval of time to maintain life and strength of the wire.

Leave a Reply